Most homes built before the 1950s used brick, stucco or wood siding. Stucco and brick required the least maintenance of the three, but after time, brick needed re-pointing and stucco needed to be repaired.

Aluminum siding was a breakthrough because it gave homeowners wonderful perks:

- Little or no maintenance

- Colour variety

- Quick installation

- Water resistance

However, the age of aluminum siding began to wane no more than a decade after it was introduced. As the aluminum product colours faded and the siding dented, another option grew in popularity. Vinyl siding made its debut and houses have never been the same since!

Find the best vinyl siding contractors today! Pick a professional based on client reviews and business transparency ratings.

Why should you consider vinyl siding?

Vinyl siding is one of the most affordable siding options on the market. For the price, this material provides very good home protection. Vinyl is a great siding product because it can come in a variety of colours and styles to suit any homeowners stylistic needs.

Vinyl comes in a huge array of colour options. It can suit any homeowner’s design dream!

Finally, vinyl is very durable. It has great water, weather, and damage resistance. It can stand up to mild hail and wind storms while keeping your home dry and safe. This product is flexible, which means that it will hold up quite well if the ground shifts.

Homeowners should focus on finding a great vinyl installation company. Gaps or poor seals will result in leaks, which could damage your home’s frame.

How do I estimate Vinyl Siding?

Why should I estimate the project before I hire an expert?

Estimating your vinyl siding project is a tedious job. However, it’s essential to the home exterior renovation process because it gives you a rough estimate and a basis to compare against professional quotes.

Estimating your own project's not your thing? Post your siding project for FREE. Local contractors can respond with project quotes.

Contractors could take advantage of you or scam you if you don’t know anything about the project. It’s always good to educate yourself before you sign a contract and provide a down payment.

Measure your home

Whether the house will be sided with vinyl, wood, steel or stucco one main element is constant in all of the siding jobs: area measurement.

Before an installation can take place, the contractor needs to know the area of your house exterior walls. This helps them understand how much material will be required for the project. They also need to know how to price the labour for the job. This will help them provide a quote for your project.

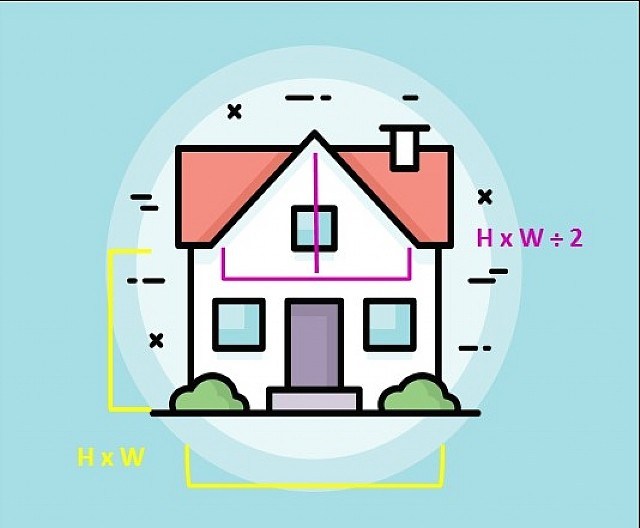

The best way to measure the exterior of a home is by dividing the home into geometric shapes. For example, the walls up to the gables can be measured as rectangles and the gable ends as triangles. Then it is just matter of finding the area.

Find your home’s siding area using the following formula:

Rectangles: Height x Width

Triangle: Height x Width then divide by 2

Add all shape areas together to get total

Have you hired a contractor before? We would like to hear about it. Write a review and help you community members!

How to measure your home

- Drawing: Buy a pad of graph paper and have a few sharp pencils ready. Get ready to draw diagrams to scale as close as possible. Draw each side of the home on a separate page.

- Supplies: Buy a good tape measure; but for the best results, get a 100-foot land surveying tape measure. This will save measuring in small sections. Although, a stiff metal tape measure works well for horizontal measurements.

- Big Picture: Measure one side at a time. Begin measuring at the front. When the two measurements have been taken, draw in the shape.

- Negative Space: Measure the windows area. Be sure to keep in mind that J-molding frames will go on top of the siding.

- Obstacles: Draw in all obstacles such as pipe stacks, electrical masts, and shutters. All these will have to be moved or moved aside.

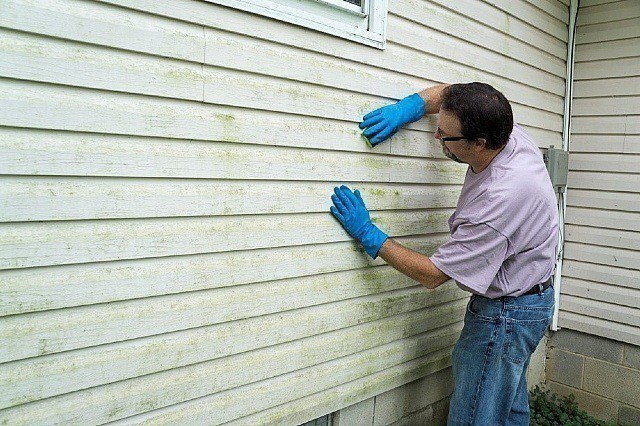

Homeowners should annually clean their vinyl siding.

- Hidden Area: Areas that are hidden from frontal view but visible on the side, like alcoves for doors, are called hidden walls. They can either be noted or drawn in a 3-D format but make sure they are drawn into your mock-up.

- Area Sum: Add the area of all the triangles and squares for each page and write them down. This will be the square footage of all the walls and can be used to calculate the amount of flat siding needed. (This number will also work for a complete stucco job because no other pieces are needed such as corner pieces)

For simplicity, multiply the home area by the price of siding per square foot. On average, siding companies change between $2 - $8. Multiply this labour fee with the area measurement of your home.

The Details

Measuring the area of your home is the first accomplishment that you can master for this project. Next, you can do the math for smaller details if you want to take this project all the way. This will give you an accurate project measurement. You can leave this part out to have a basic understanding of the potential project cost. For accuracy, consider including the following:

- Linear Numbers: You need to the find linear foot measurements to account for soffits, gutters, downspouts, corner pieces, inner corner pieces, fascia and starter strips. You can find the price of these materials from any building supply catalog. A catalog will also show you what lengths these pieces are sold in. Go back to the diagrams and figure these out for each page. For example:

- If a corner is nine feet high, then one piece of the ten-foot vinyl corner is needed.

- J-channel goes along the top of the siding and around windows and doors.

- F-molding holds in the soffits on each side so this amount has to be doubled.

Don’t forget to factor J-channel and window frames when estimating the area of your home!

- Amount of Siding: Begin by accounting for waste. Add 10% onto the area of your home. Multiply this area by the cost of the siding. Bear in mind that siding may be sold in measurements of 100 ft2. So, you must divide the area of your home (plus 10% wastage) by 100 ft2, and then multiply this by the cost of the siding. For example:

- The area of your home is 1425 ft2

- Multiply the area by 10% = 1568 ft2

- Divide 1568 by the amount the siding is sold in (e.g. priced by 100ft) = 15.68

- Multiply the cost of the siding by this number: $75 x 15.68 = $1175.63.

- This is the total of the flat siding.

- Corners and Details: Check the price of the corner materials and count up the number of corners on the home. Multiply the number of corners by the price of the material and add up the costs for inside and outside corners. For example:

- If there are four outside corners at $10 each this would be $40 and two inside corner at $8 would be $16.

- Do this for the gutters, fascia, soffits, downspouts and starter strips.

- Do this for the starter strip, F-moldings and J-channel.

- Other Materials: Vinyl siding isn’t necessarily attached to your home frame. Other materials ma be required to successfully complete this project. You may not know this until an expert gives your a project consultation. Other materials include:

- A wall-leveling product made from foam sandwiched between two sheets of thin aluminum. This makes the surface level and smooth. It also adds R-value to the home for insulation. A 3/8-inch wall leveling product will add about $350 to the project.

- Nails will be needed for the fascia and siding. Your contractor can calculate the number of nails needed for the project based on the square footage.

- Caulking for sealing gaps around windows and doors.

For best results for a siding job consult our contractor directory or simply post your siding project online and get free estimates.

Posted by: Kim Kinrade